problem

Do you have any of the following in-seal

defects or sealing inspection issues?

-

Missed defects due to visual inspection/lack of reliable checksStaff shortages make it difficult to manage increased demandTime consuming inspection leads to a long lead time

solution

The Solution

The Solution

With a customer satisfaction rating of 97% from customers in both Japan and overseas, Shikoku Instrumentation's Heat Seal Inspection System is a pioneer of heat seal inspection.

features

Why choose the Heat Seal Inspecion System?

-

Highly

accurate heat seal defect detection

The main feature of our inspection system is its high accuracy. It can detect defects such as weak adhesion and incomplete sealing which cannot be detected by image processing devices or X-ray devices.

-

Fully

automated inspection

Increase productivity by reducing processes.

Increase profits by reducing costs.

-

High-speed

inspection without stopping production.

Inspect up to 125 bags per minute, 24 hours a day, 365 days a year, without stopping production.

-

Simple

and easy to use

See inspection results from a glance from the judge screen or check the temperature from the wave screen.

-

Useful

for traceability

See when, where, by whom and how a faulty batch was produced by checking records from up to four years ago.

Contact us if you have any questions!

Free sample test

Send us your pouches and we will test them

with our demo machine and send you the results.

function

The Three Functions of the

Heat Seal Inspection System

1Highly precise inspection

Detect seal faults which cannot be detected by manual

inspection or image processing.

-

01

In-seal

defects

Contents trapped in the seal area.

Contents trapped in the seal area.

-

02

Incomplete

sealing

Weak adhesion.

Weak adhesion.

-

03

Slanted

seal

Unaligned sealing.

Unaligned sealing.

-

04

Overlapping

sealing

Two pouches sealed together.

Two pouches sealed together.

-

05

Wrinkles

Folds and wrinkles in the sealing area.

Folds and wrinkles in the sealing area.

2Products which can be inspected

Retort pouches and other pouches,

including doypack and stand up pouches.

-

01

Ready meals

- Boil in the bag rice

- Stew and soup

- Curry sauce, pasta sauce

-

02

Powdered / granulated food

- Coffee

- Protein powder

- Spices

-

03

Confectionary

- Chocolate sharing bag

- Candy/gummy sweets

- Biscuits

-

04

Pet food

- Dog food and cat food

(wet and dry)

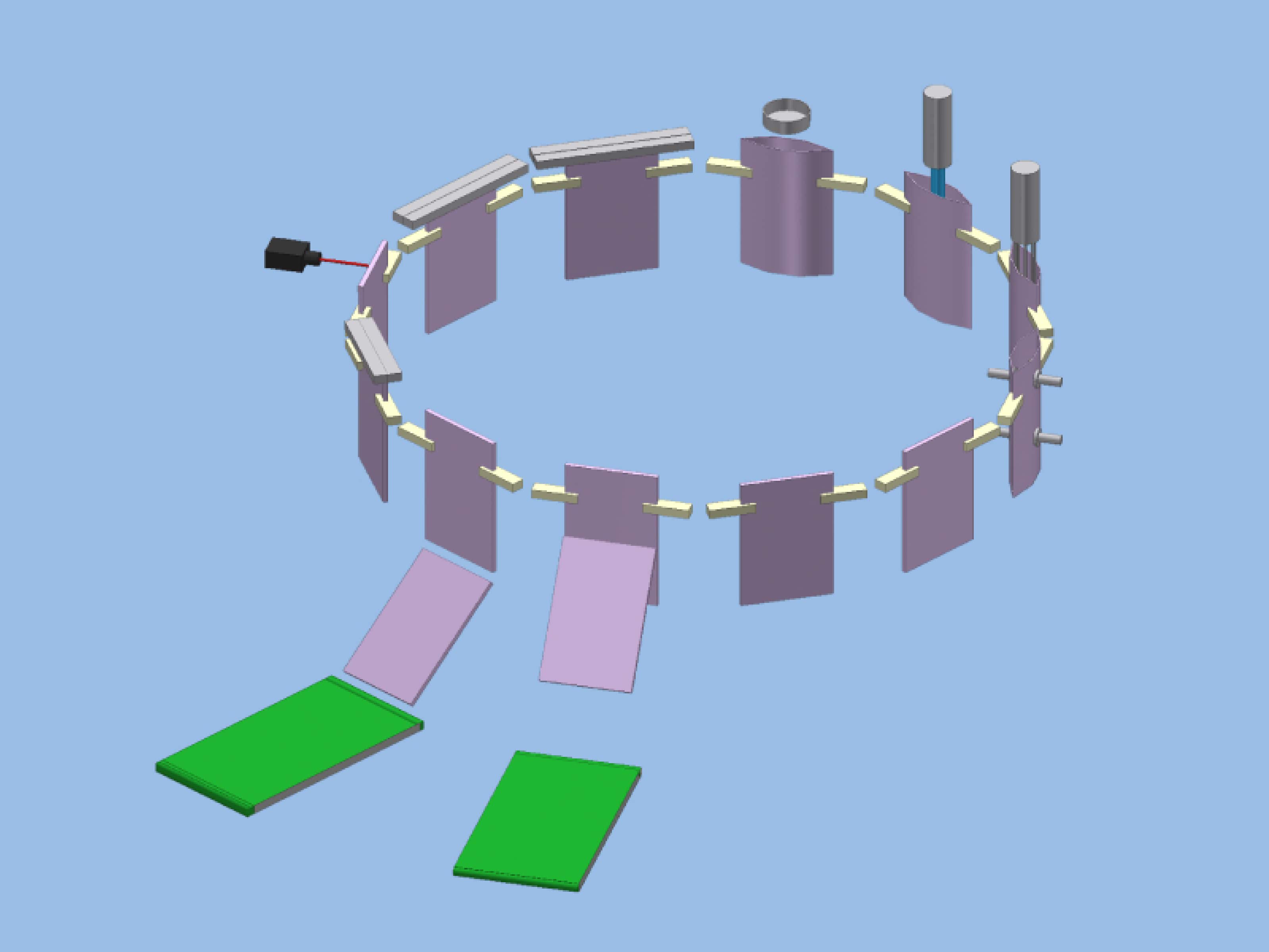

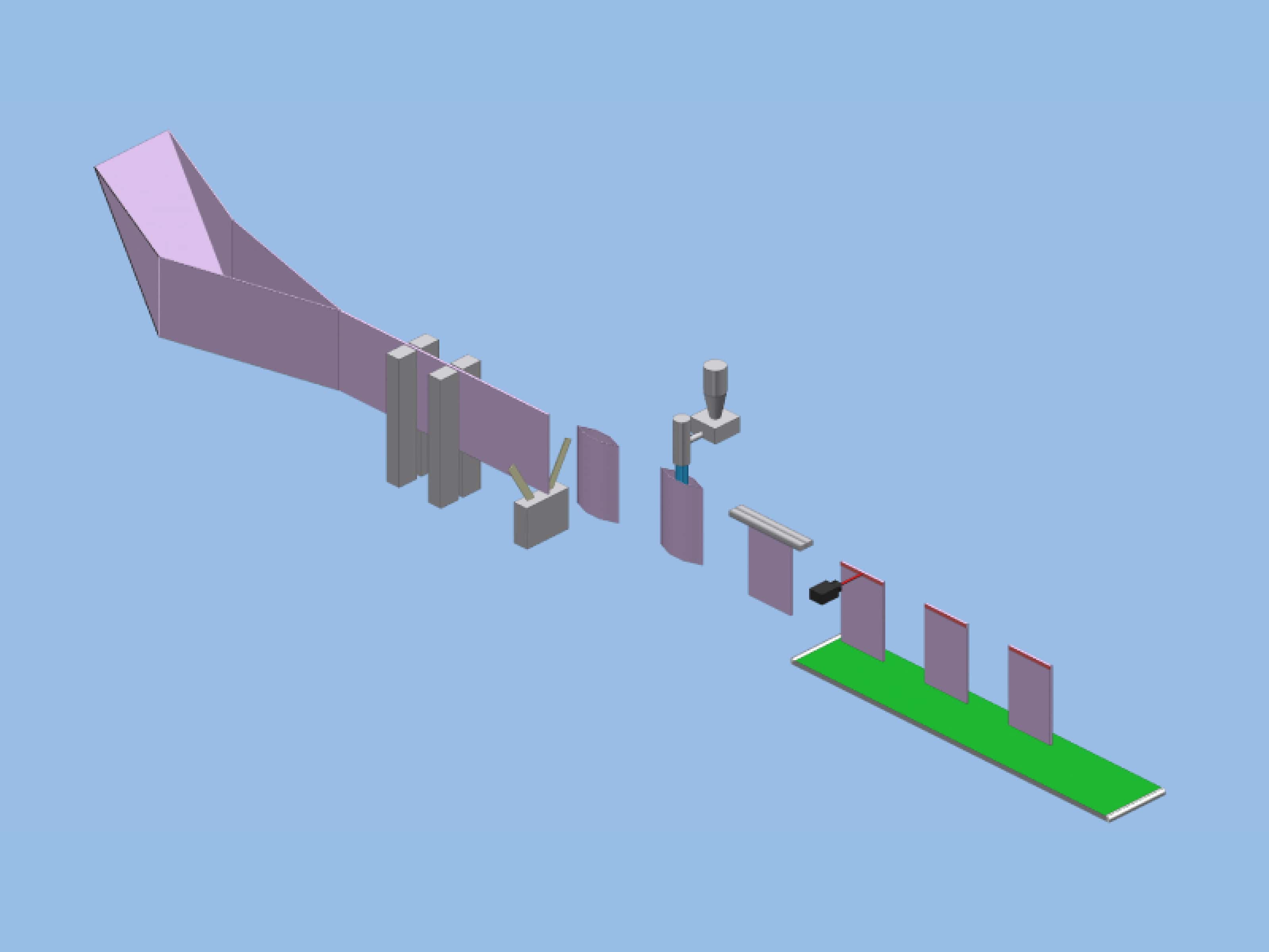

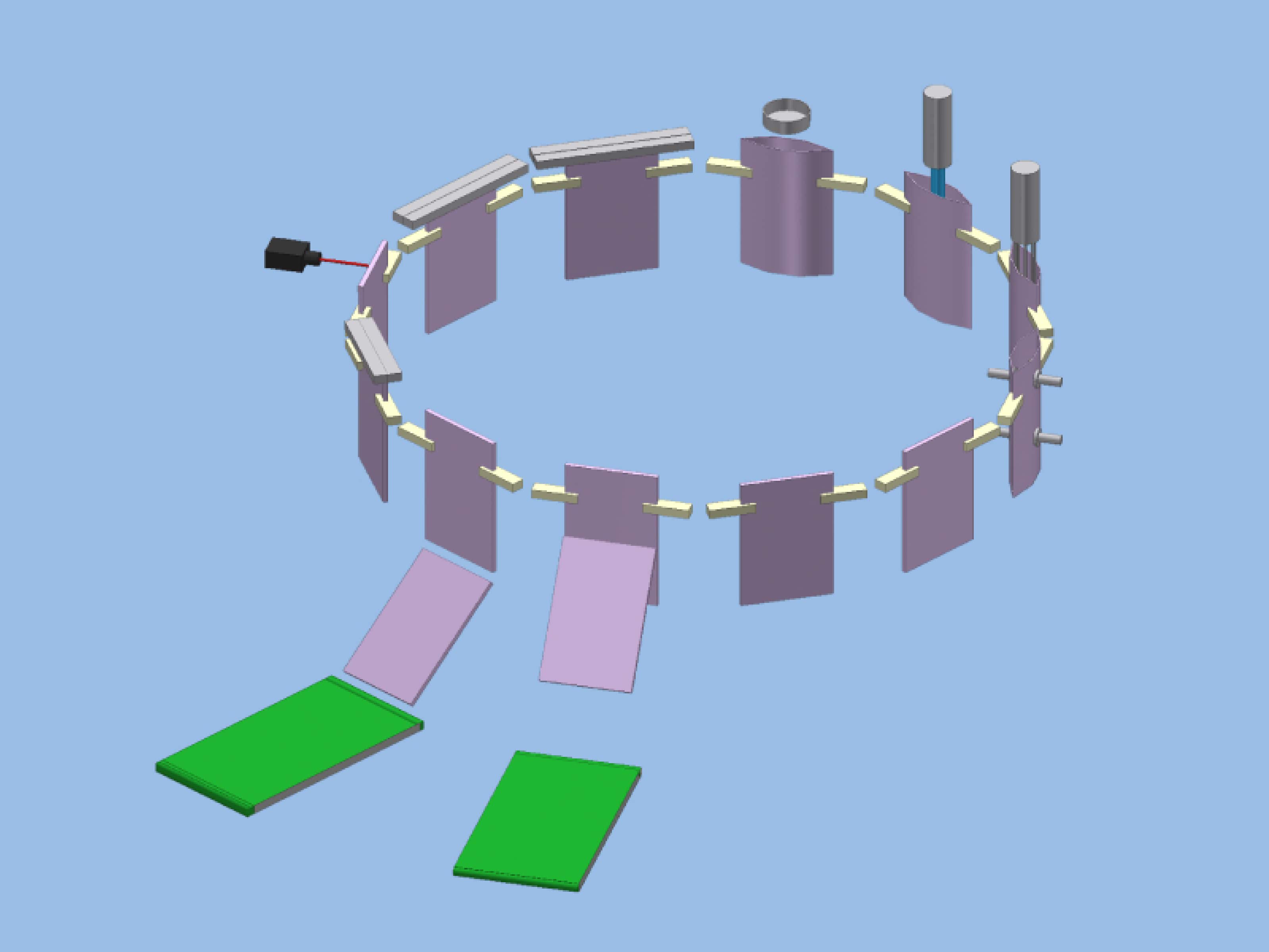

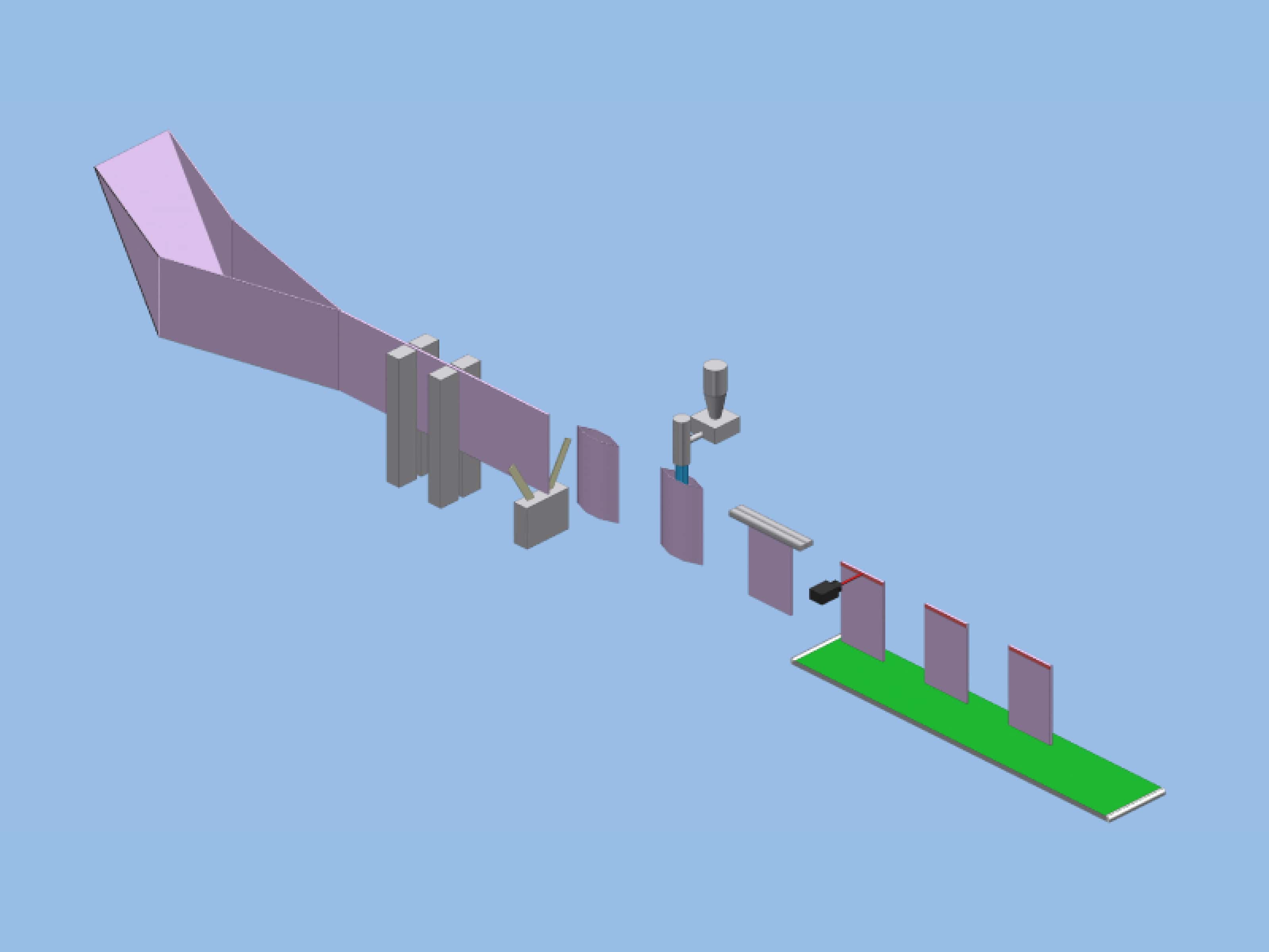

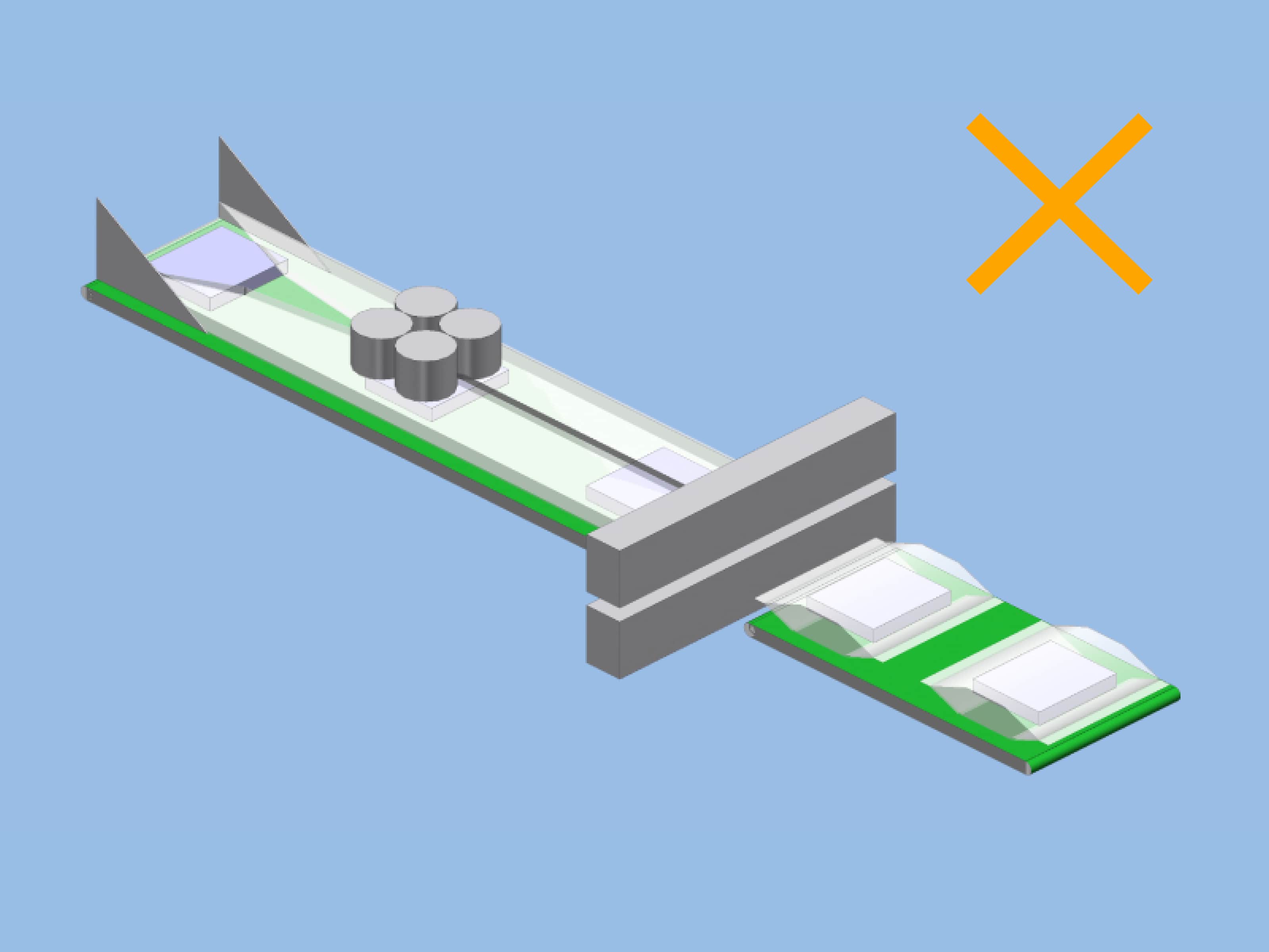

3Compatible machines

Can be fitted onto most rotary and packaging machines.

The type of sensor is also suited to the conditions.

-

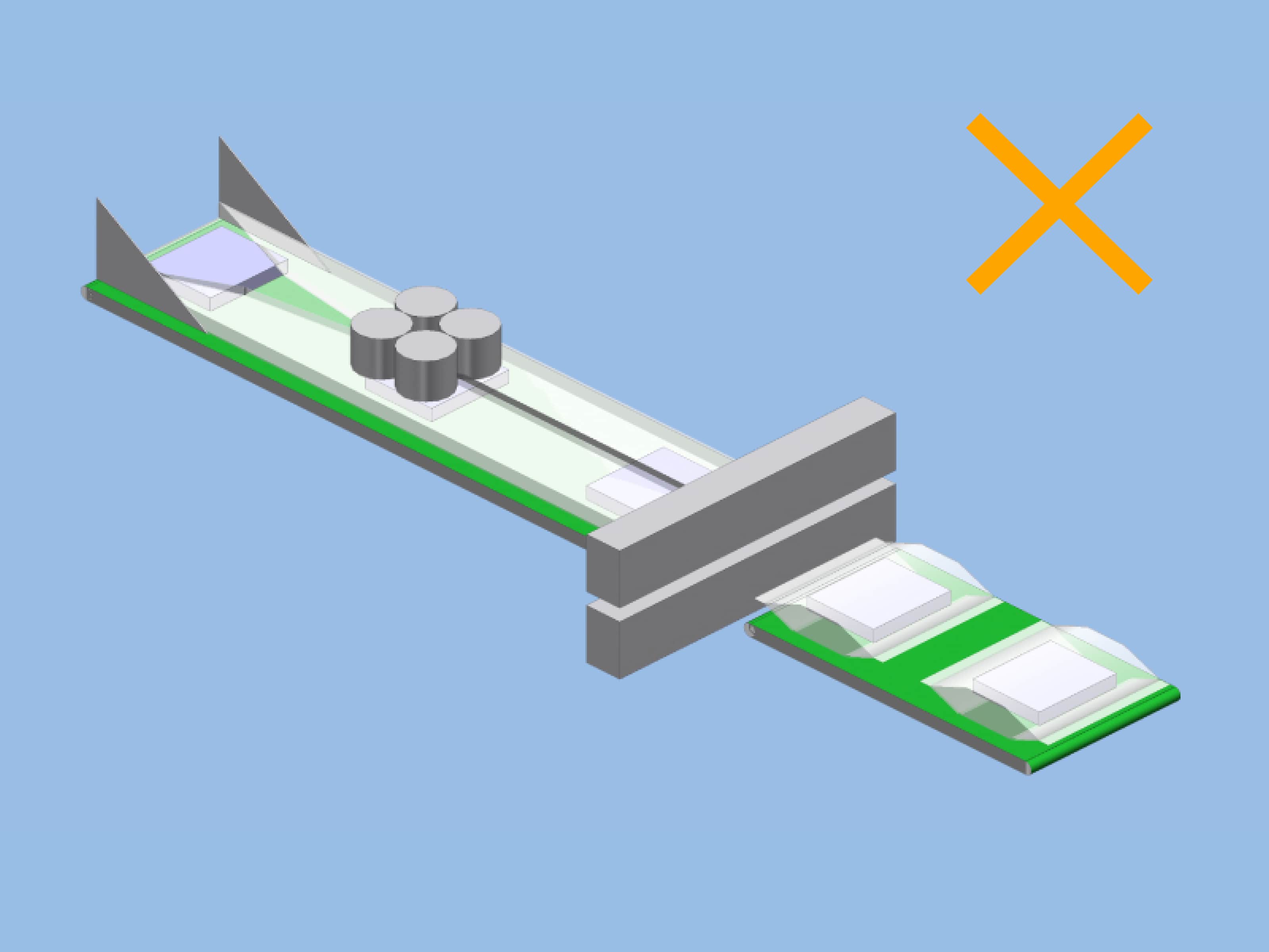

NB not suitable for use with pouch vacuum machines.

Premade pouch filing and packing machine

-

Compatible with some

types only.

Flowpack pouch making and filling machines

-

Cannot be handled.

Pillow type packing machine

spec

Product specification

Dimensions

(width 500 mm / length 400 mm / depth 250 mm)

- Items which can be inspected

- Premade pouch filling and packing machine

- Inspection quantity

- Max 125 bags per minute (using a double-barreled filling and packing machine)

- Inspection system

- Non-contact temperature measurement system

- Functions

- Touch panel, learning function, able to store data for up to 999 product types

- Inspection history

- Up to 20 million screenshots (depending on the inspection type)

- Power

- AC220V or 230V, capacity 300VA

- Types of products which can be inspected

- Curry, pasta sauces, soup

Inspection screen (example)

Up to two infrared sensors can be connected simultaneously and can be used for detection of a wider area. Detection in two stages is also possible by installing one sensor after the first sealing station and another after the second sealing station.

map

Our partners &

Our clients

- Our clients:

- Europe(France,Italy,Spain),South America(Mexico,Brazil,Peru)

Malaysia,Australia,South Korea,Vietnam,Singapore,Taiwan

- Our partners:

- France,Thailand,South Korea,Australia,Italy,Taiwan

- Our partners

- France

BFR SYSTEMS

Parc Technologique 24, rue du Bois Chaland CE 2934 LISSES 91029 EVRY CEDEX FRANCE

Email:bfesystems@bfrsystems.com

Tel: (33) 1 69 11 90 10

Fax commercial:(33) 1 69 11 90 01,

Fax Technique:(33) 1 69 11 90 02

Website: https://www.bfrsystems.com/

Italy

X-Pack

Via dell'Artigianato 1 - 35036 Montegrotto Terme (PD)

Tel: +39(0)499125934

Email: service@x-pack.it

Website: https://www.x-pack.it/

South Korea

PeakmanSP Co., Ltd

Address: 150, Jojeong-daero, Hanam-si, Gyeonggi-do, 12930, South Korea

Units 657, 658, 659 (Deokpung-dong, ITeco)

Tel : +82(0)2-577-5982

Fax : 031-790-4149

Email: order@peakmansp.co.kr

Website: https://www.peakmansp.co.kr/

Thailand

Sripipat Engineering Co., Ltd

Address: 165, 165/1 Soi Sukhumvit 93 (Phungmi), Sukhumvit Road, Bangchak, Phra Khanong, Bangkok 10260, Thailand

Tel: +66(0)2-331-9103-6

Line: @spponline

Email: sripipat@sripipat.co.th

Website: https://www.sripipat.co.th/

Taiwan

Biedermi Enterprise co., LTD

畢德麥企業有限公司

Address: No. 15, Aly. 16, Ln. 228, Sec. 2, Nankan Rd., Luzhu Dist., Taoyuan City 338015, Taiwan (R.O.C.)

Tel: +886-3-321-8572

Fax: +886-3-321-8397

Email: btm2188@hotmail.com / biedermi@ms23.hinet.net

Website: https://www.en.btm-pack.com.tw/

Australia

Process Plant Network Pty Ltd

Address: 3-5 Capital Drive, DANDENONG SOUTH Victoria 3175

Tel: +61 3 9791 7011

Email: sales@processplant.com

Website: https://www.processplant.com/

Contact us if you have any questions!

Free sample test

Send us your pouches and we will test them

with our demo machine and send you the results.

faqs

faqs

-

Are there any restrictions regarding the pouch shape?

The top horizontal seal of a premade pouch which has been sealed on three sides can be inspected. Some pouches with unusual shapes can also be inspected. Please contact us to check.

-

Can it be installed on my packaging machine?

Our sensors can be installed immediately after the first seal on single and twin rotary type packaging machines. Please tell us the manufacturer and model of your packaging machine so we can advise you as to whether installation is possible or not.

-

How long is the installation process?

Installation and commissioning can be carried out on holidays while production is stopped. Production must be stopped for approximately one day to install one unit. Then the system is tested during normal production. We also offer operational training. The whole process takes two days.

-

Do you provide after-sales support?

We aim to respond in a timely manner and work closely with our overseas

partners to solve any issues as quickly as possible.

With a customer satisfaction rating of 97% from customers in both Japan and overseas, Shikoku Instrumentation's Heat Seal Inspection System is a pioneer of heat seal inspection.

features Why choose the Heat Seal Inspecion System?

-

Highlyaccurate heat seal defect detection

The main feature of our inspection system is its high accuracy. It can detect defects such as weak adhesion and incomplete sealing which cannot be detected by image processing devices or X-ray devices.

-

Fullyautomated inspection

Increase productivity by reducing processes.

Increase profits by reducing costs. -

High-speedinspection without stopping production.

Inspect up to 125 bags per minute, 24 hours a day, 365 days a year, without stopping production.

-

Simpleand easy to use

See inspection results from a glance from the judge screen or check the temperature from the wave screen.

-

Usefulfor traceability

See when, where, by whom and how a faulty batch was produced by checking records from up to four years ago.

Contact us if you have any questions!

Free sample test

Send us your pouches and we will test them

with our demo machine and send you the results.

function

The Three Functions of the

Heat Seal Inspection System

1Highly precise inspection

Detect seal faults which cannot be detected by manual

inspection or image processing.

inspection or image processing.

-

01

In-seal

defectsContents trapped in the seal area. -

02

Incomplete

sealingWeak adhesion. -

03

Slanted

sealUnaligned sealing. -

04

Overlapping

sealingTwo pouches sealed together. -

05

Wrinkles

Folds and wrinkles in the sealing area.

2Products which can be inspected

Retort pouches and other pouches,

including doypack and stand up pouches.

including doypack and stand up pouches.

-

01

Ready meals

- Boil in the bag rice

- Stew and soup

- Curry sauce, pasta sauce

-

02

Powdered / granulated food

- Coffee

- Protein powder

- Spices

-

03

Confectionary

- Chocolate sharing bag

- Candy/gummy sweets

- Biscuits

-

04

Pet food

- Dog food and cat food

(wet and dry)

- Dog food and cat food

3Compatible machines

Can be fitted onto most rotary and packaging machines.

The type of sensor is also suited to the conditions.

The type of sensor is also suited to the conditions.

-

NB not suitable for use with pouch vacuum machines.

Premade pouch filing and packing machine

-

Compatible with some

types only.Flowpack pouch making and filling machines

-

Cannot be handled.

Pillow type packing machine

spec Product specification

Dimensions

(width 500 mm / length 400 mm / depth 250 mm)

- Items which can be inspected

- Premade pouch filling and packing machine

- Inspection quantity

- Max 125 bags per minute (using a double-barreled filling and packing machine)

- Inspection system

- Non-contact temperature measurement system

- Functions

- Touch panel, learning function, able to store data for up to 999 product types

- Inspection history

- Up to 20 million screenshots (depending on the inspection type)

- Power

- AC220V or 230V, capacity 300VA

- Types of products which can be inspected

- Curry, pasta sauces, soup

Inspection screen (example)

Up to two infrared sensors can be connected simultaneously and can be used for detection of a wider area. Detection in two stages is also possible by installing one sensor after the first sealing station and another after the second sealing station.

map

Our partners &

Our clients

- Our clients:

- Europe(France,Italy,Spain),South America(Mexico,Brazil,Peru)

Malaysia,Australia,South Korea,Vietnam,Singapore,Taiwan

- Our partners:

- France,Thailand,South Korea,Australia,Italy,Taiwan

- Our partners

- France

BFR SYSTEMS

Parc Technologique 24, rue du Bois Chaland CE 2934 LISSES 91029 EVRY CEDEX FRANCE

Email:bfesystems@bfrsystems.com

Tel: (33) 1 69 11 90 10

Fax commercial:(33) 1 69 11 90 01,

Fax Technique:(33) 1 69 11 90 02

Website: https://www.bfrsystems.com/

Italy

X-Pack

Via dell'Artigianato 1 - 35036 Montegrotto Terme (PD)

Tel: +39(0)499125934

Email: service@x-pack.it

Website: https://www.x-pack.it/

South Korea

PeakmanSP Co., Ltd

Address: 150, Jojeong-daero, Hanam-si, Gyeonggi-do, 12930, South Korea

Units 657, 658, 659 (Deokpung-dong, ITeco)

Tel : +82(0)2-577-5982

Fax : 031-790-4149

Email: order@peakmansp.co.kr

Website: https://www.peakmansp.co.kr/

Thailand

Sripipat Engineering Co., Ltd

Address: 165, 165/1 Soi Sukhumvit 93 (Phungmi), Sukhumvit Road, Bangchak, Phra Khanong, Bangkok 10260, Thailand

Tel: +66(0)2-331-9103-6

Line: @spponline

Email: sripipat@sripipat.co.th

Website: https://www.sripipat.co.th/

Taiwan

Biedermi Enterprise co., LTD

畢德麥企業有限公司

Address: No. 15, Aly. 16, Ln. 228, Sec. 2, Nankan Rd., Luzhu Dist., Taoyuan City 338015, Taiwan (R.O.C.)

Tel: +886-3-321-8572

Fax: +886-3-321-8397

Email: btm2188@hotmail.com / biedermi@ms23.hinet.net

Website: https://www.en.btm-pack.com.tw/

Australia

Process Plant Network Pty Ltd

Address: 3-5 Capital Drive, DANDENONG SOUTH Victoria 3175

Tel: +61 3 9791 7011

Email: sales@processplant.com

Website: https://www.processplant.com/

Contact us if you have any questions!

Free sample test

Send us your pouches and we will test them

with our demo machine and send you the results.

faqs faqs

-

Are there any restrictions regarding the pouch shape?

The top horizontal seal of a premade pouch which has been sealed on three sides can be inspected. Some pouches with unusual shapes can also be inspected. Please contact us to check.

-

Can it be installed on my packaging machine?

Our sensors can be installed immediately after the first seal on single and twin rotary type packaging machines. Please tell us the manufacturer and model of your packaging machine so we can advise you as to whether installation is possible or not.

-

How long is the installation process?

Installation and commissioning can be carried out on holidays while production is stopped. Production must be stopped for approximately one day to install one unit. Then the system is tested during normal production. We also offer operational training. The whole process takes two days.

-

Do you provide after-sales support?

We aim to respond in a timely manner and work closely with our overseas partners to solve any issues as quickly as possible.